machine shop

OUR MACHINE SHOP

At Riverside Performance Engines’ full-scale Machine Shop, our expert machinists are equipped to restore, remanufacture, or build engine components to their original—or even improved—performance. Whether you’re after a full engine build or a precision crankshaft balance, we’re your one-stop shop. By blending versatile component expertise with cutting-edge machining services, we offer unmatched precision and performance under one roof. From industrial and performance engines to every critical component in between, our team delivers quality you can rely on.

-

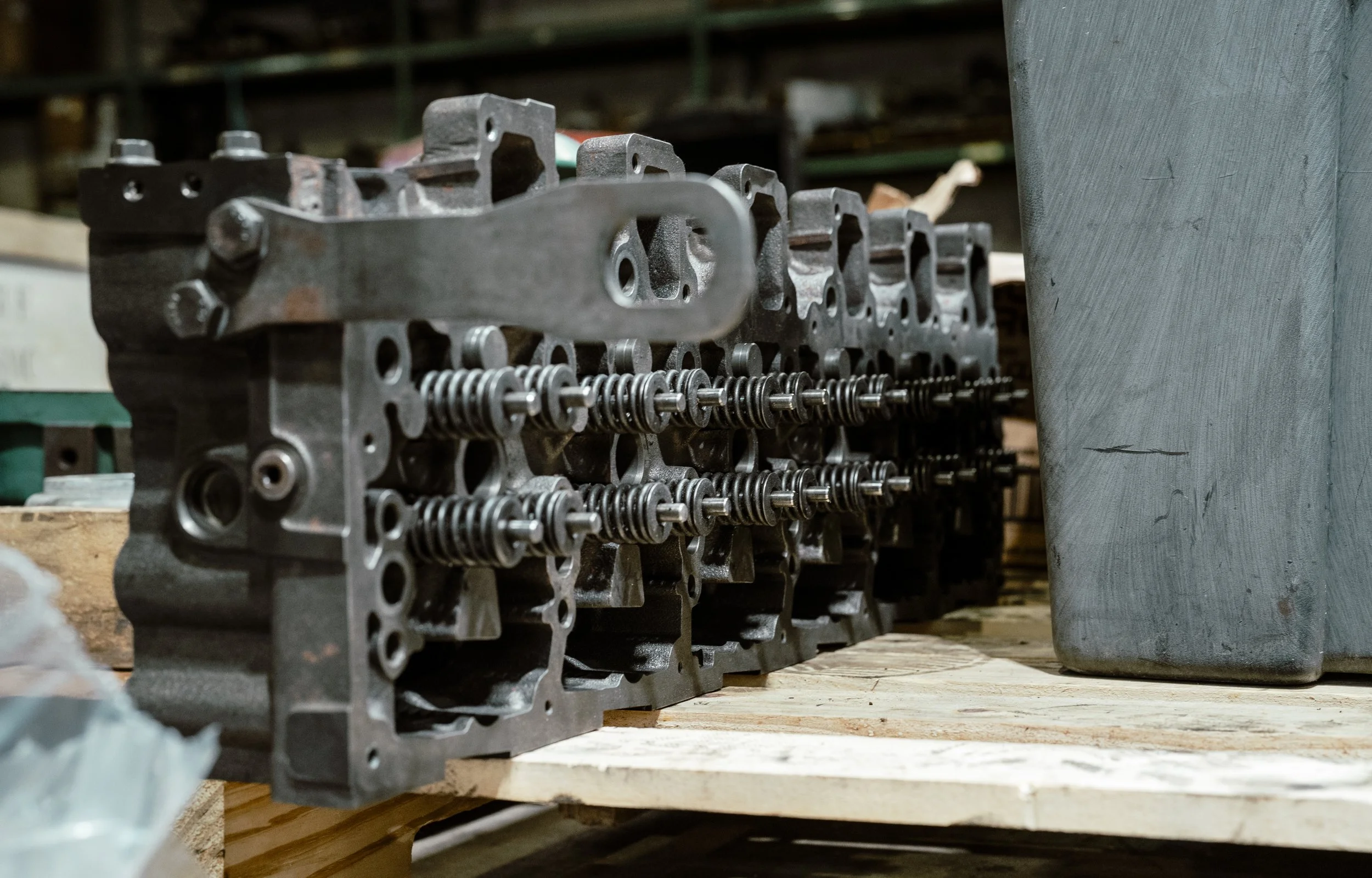

Complete Engine Rebuilds

We meticulously restore and reuse as many of your engine’s original components as possible. Every rebuild is machined with CNC precision, delivering performance that’s “like new”—but even more reliable.

Crankshaft Balancing & Polishing

Balancing enhances performance by promoting smoother engine operation, reducing energy loss, and extending engine life. Polishing ensures that bearing surfaces and journals are ultra-smooth, improving longevity and consistency.

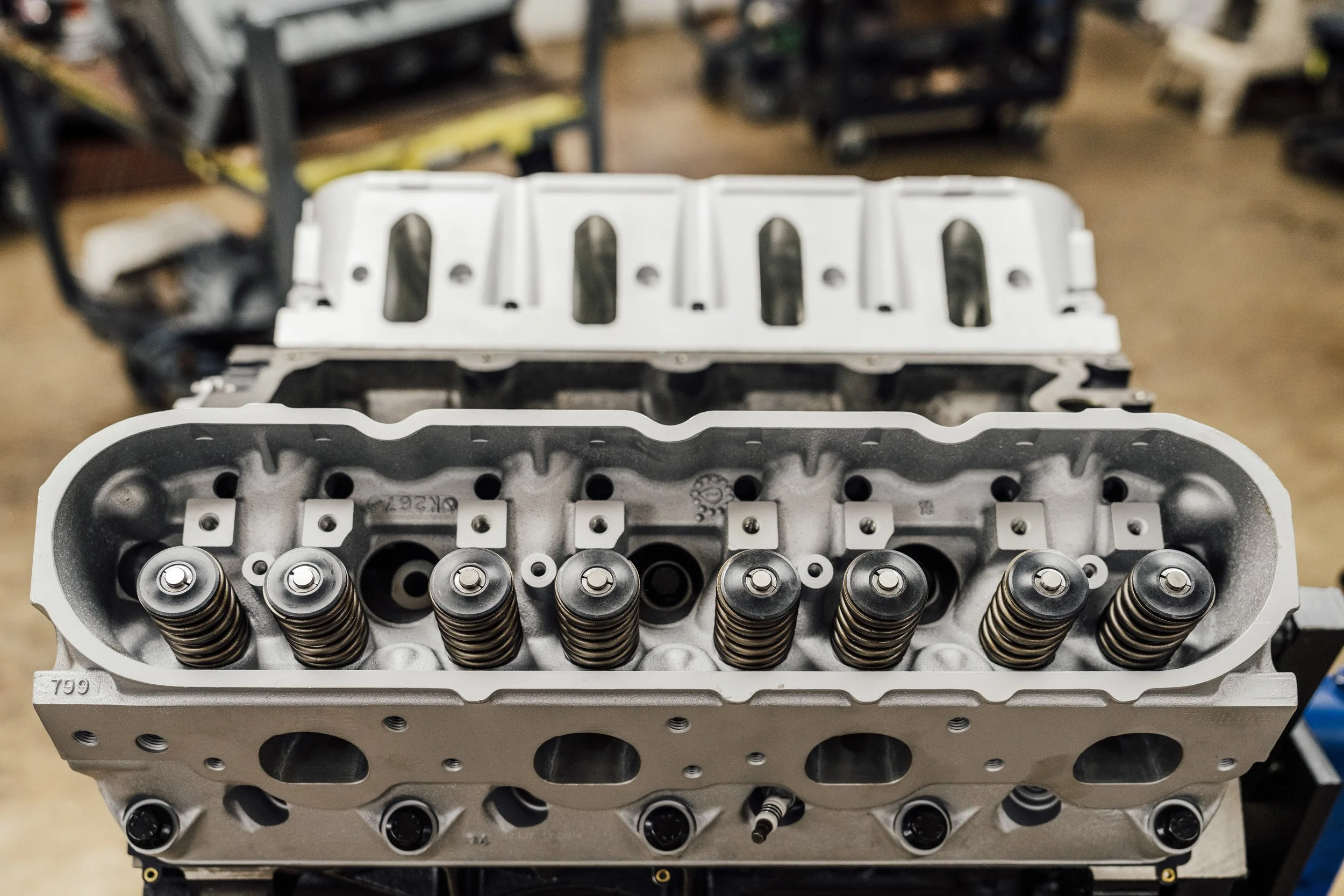

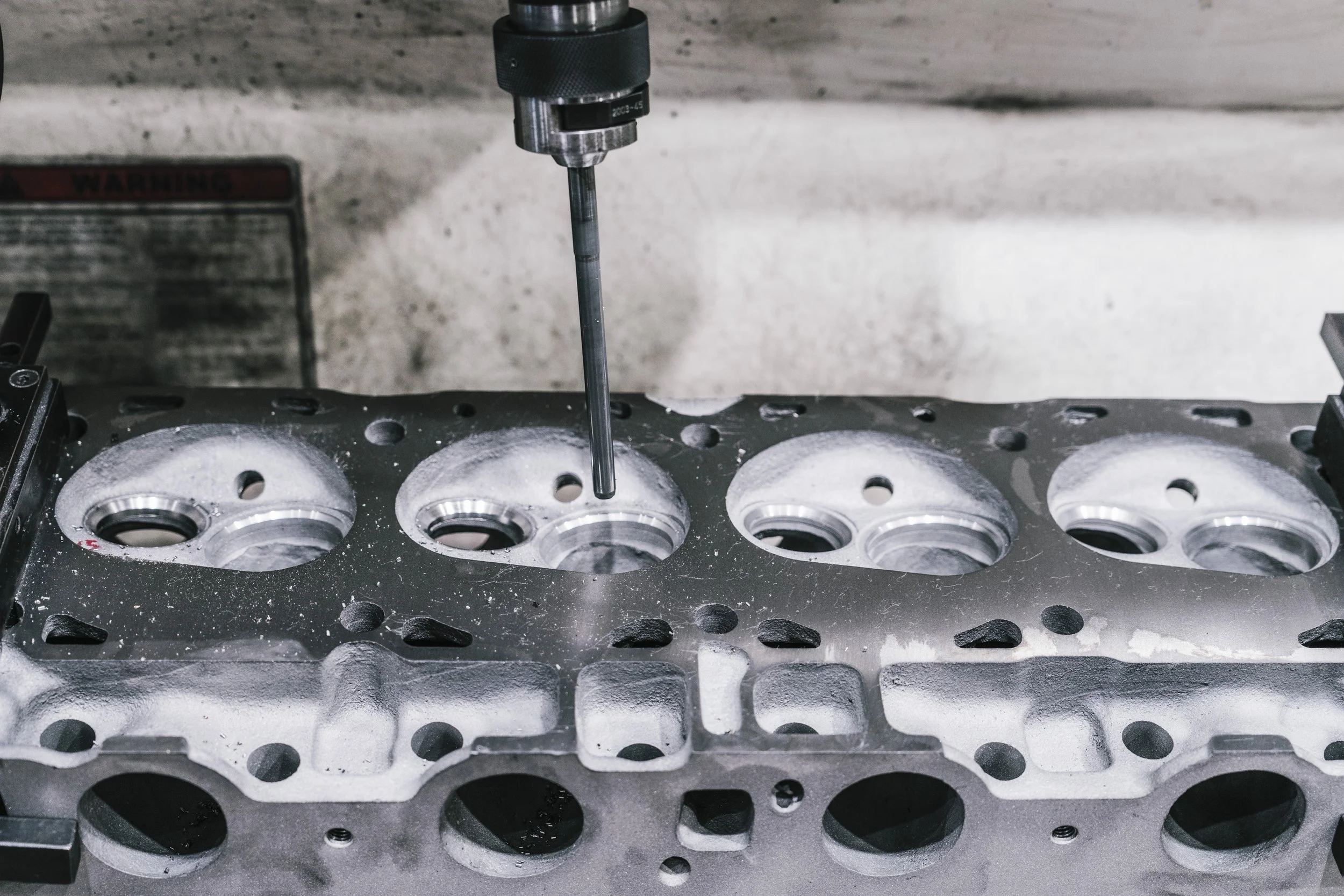

Cylinder Head Work

Clean, surface, valve job and rebuild. Crankshaft turning, polishing and grinding. Pistons, ultrasonic cleaning and valve work.

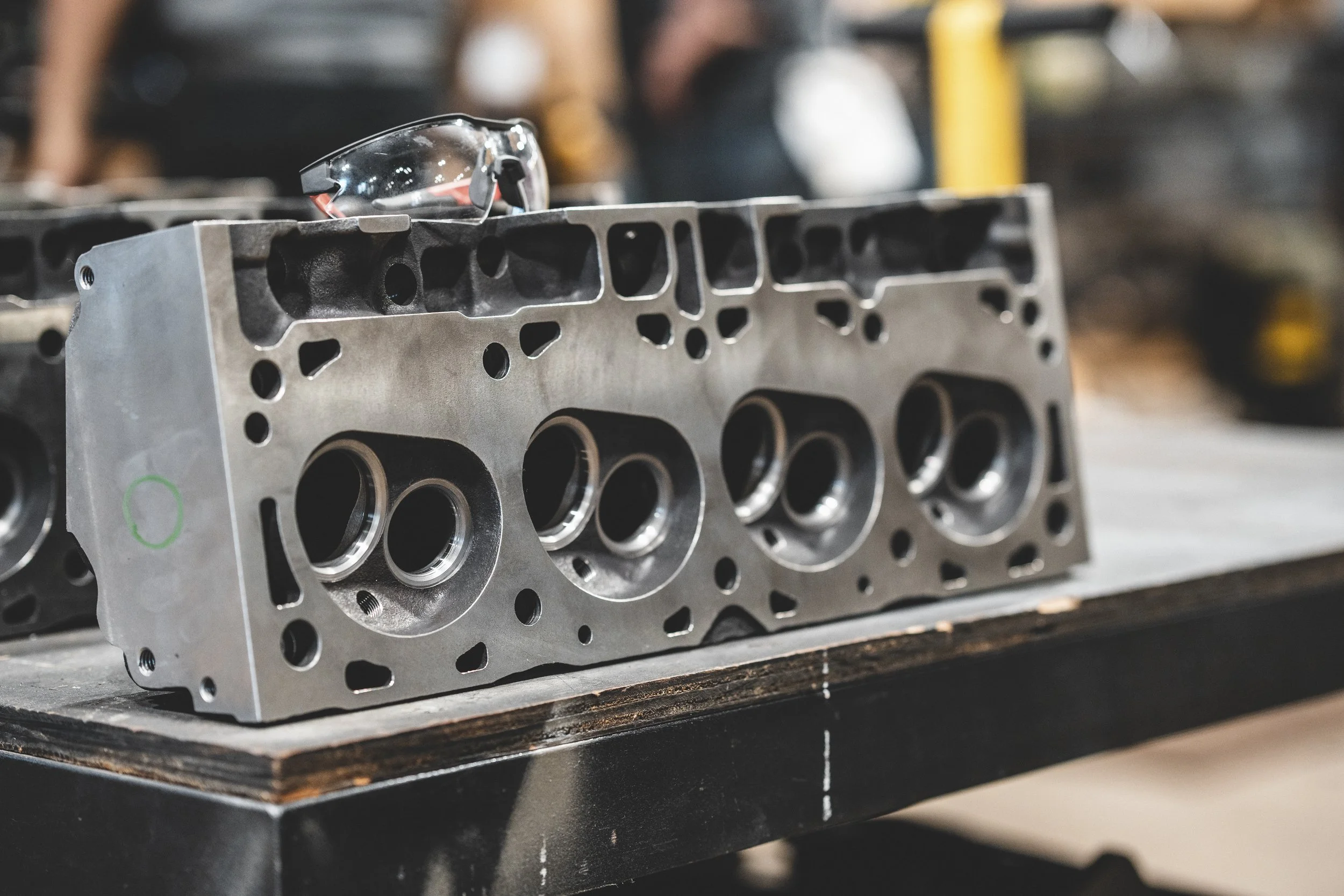

Block Work

Bore, deck, hone, cam installation and more!

Cylinder Sleeving

In applications requiring reduced cylinder diameter, we install high-quality Melling Darton or Power-bore sleeves to ensure precise performance every time.